Development and production of special gearboxes

With application-specific versions of all gearbox types, electrically, hydraulically or pneumatically driven, as well as their combinations, we solve all the special applications in mechanical engineering in the drive torque range up to 10,000 Nm, for whose demanding concepts and problem solutions the use of a standard gearbox is not sufficient.

We also provide additional components for special applications in the integration of flexible and switchable clutches, brakes or electronic components such as sensors and measuring probes.

The production of special gearboxes requires precise planning, development and execution. Here you can discover exactly what such a joint project can look like, from the idea to the installed gearbox, and what services CHEMNITZER ZAHNRADFABRIK can support you with.

We sell engineering –

with excellent hardware as an added value.

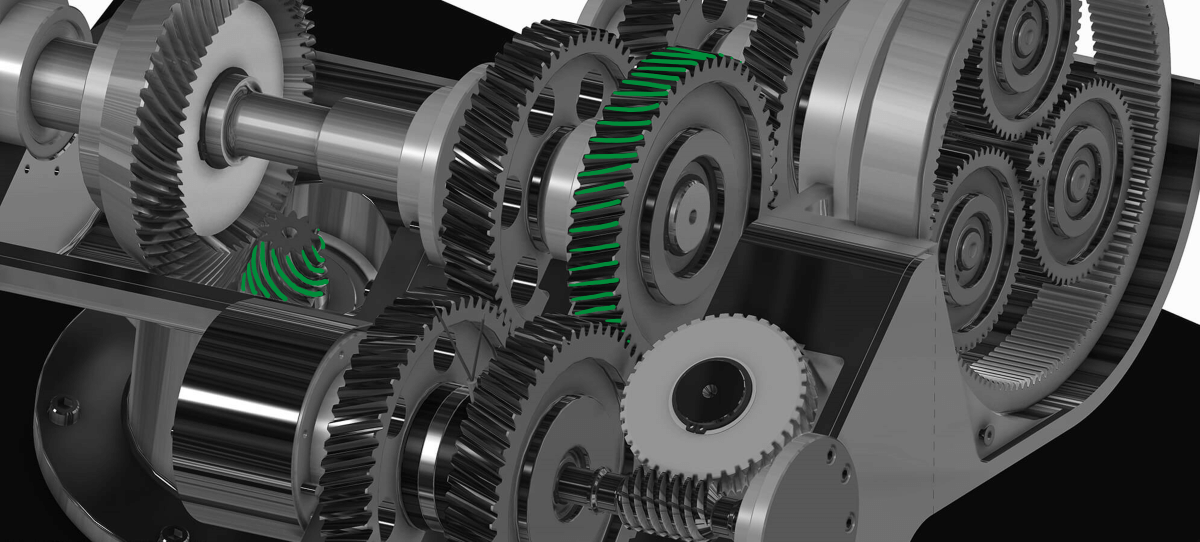

A gearbox is a mechanical component that transmits power from one part of a machine to another. It consists of a series of gears that mesh together to change and control the speed, torque or direction of mechanical energy. It allows the machine to operate efficiently under different conditions by adjusting the gear ratio accordingly.

In a gearbox, the motor power is transmitted to the gears via the input shaft. Depending on the selected transmission ratio, the output shaft rotates at a different speed than the input shaft, allowing the speed and torque of the output to be controlled.

There are virtually no limits to the technical possibilities within the boundaries of physics. We have mastered all types, from helical and worm gearboxes to bevel gearboxes and their combinations. In the end, the requirements profile of the application determines which design is the right one for your special gearbox.

Due to our very high level of vertical integration, we have few limits. The current state of our production technology enables us to solve applications in the drive torque range up to 10,000 Nm.

It always starts with a trusting dialogue with our customer. With the necessary information about the application and basic data such as speed and torque range, connection dimensions or unusual ambient conditions. On this basis, our design department will then design the right gearbox for your specific requirements. We maintain close communication with you throughout the entire development and production process.

Special gearboxes are used for special applications where conventional standard gearboxes are not sufficient or special requirements need to be met. This can actually occur in any industry – so wherever sophisticated drive technology is used, you will find individual and customized special gearboxes.