Environmental

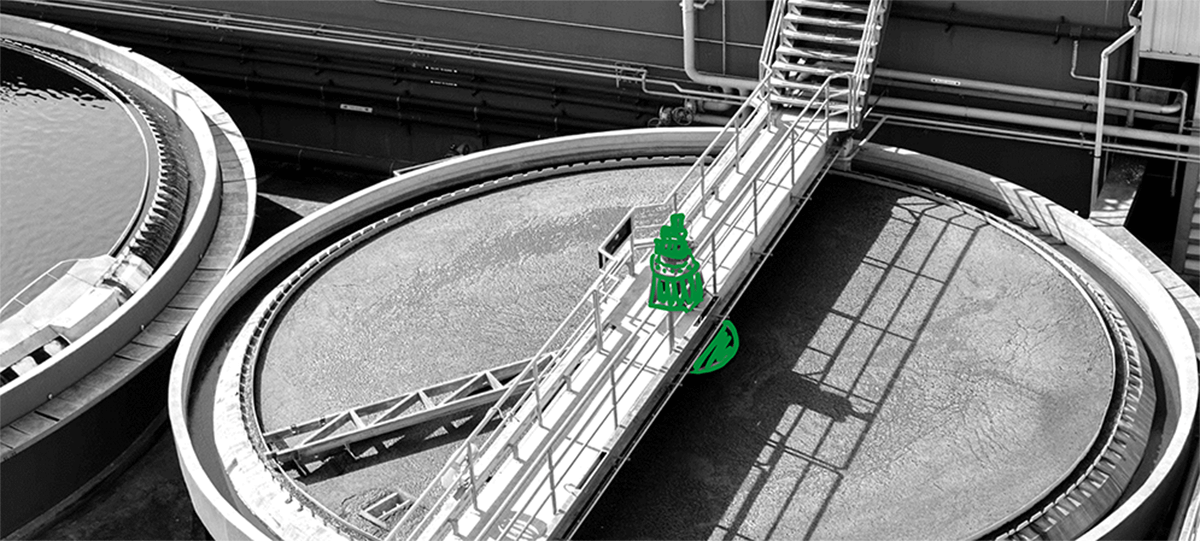

The industry continues to grow rapidly in importance and places high demands on the technologies used. Systems designed to protect the environment require high operational reliability, durability and maintenance-free operation over long periods of time. We meet the challenges of a clean environment with innovative gearbox construction.

Cases of application

- single-stage and two-stage underwater planetary gear, for water depths of up to 15 m, high efficiency

- underwater helical gear with sealing oil chamber and leakage monitoring; series in different performance/ratio variants

- gears for submerged aerators with a power of up to 90 KW

Power transmission for every - really every - application.

What do our customers do with our gearboxes?

Spinning, compressing, pumping, labelling, sieving, stirring, sawing, welding, honing, drilling, navigating, screwing, printing, mangling, positioning, deep drawing, mowing, packing, cutting, reshaping, enveloping, fertilising, milling, flying, burning, washing, punching, compressing, braking, folding, kneading, weaving, winding, mixing, screwing, pressing, spraying, gluing, dosing, diagnosing, sealing, interlocking, pulling, perforating, testing, assembling, cutting, moving, transporting...

What purpose does your machine fulfil?