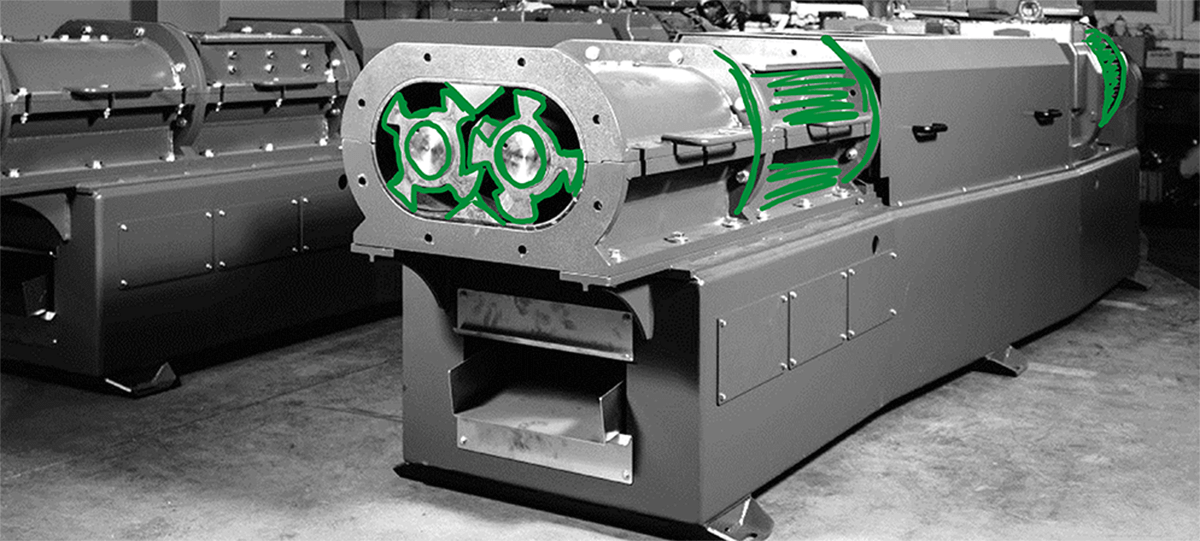

Extruders

Customised special gearboxes are essential in extruders, ensuring precise and controlled sequences at various stages of the extrusion process with optimised torque transmission and speed control, whether for plastics, food, pharmaceuticals or other materials.

They enable uniform material processing and moulding, which increases product quality and efficiency. Thanks to their customised design, they are able to meet specific requirements such as high torques, precise positioning and durability under extreme operating conditions. In addition, customised special gearboxes help to minimise energy losses and reduce downtime, which optimises the production capacities of the extruder lines and lowers the total cost of ownership.

Power transmission for every - really every - application.

What do our customers do with our gearboxes?

Spinning, compressing, pumping, labelling, sieving, stirring, sawing, welding, honing, drilling, navigating, screwing, printing, mangling, positioning, deep drawing, mowing, packing, cutting, reshaping, enveloping, fertilising, milling, flying, burning, washing, punching, compressing, braking, folding, kneading, weaving, winding, mixing, screwing, pressing, spraying, gluing, dosing, diagnosing, sealing, interlocking, pulling, perforating, testing, assembling, cutting, moving, transporting...

What purpose does your machine fulfil?