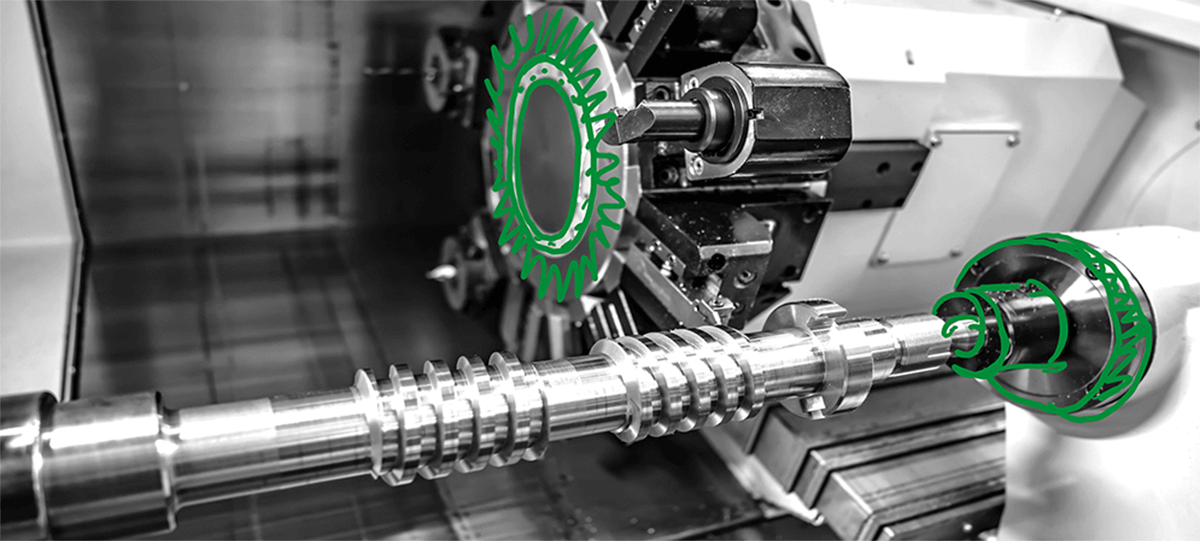

Machine tools

When dealing with high drive torques and complicated motion sequences, our special gearboxes are a powerful and economical addition to direct drives.

These gearboxes are used in CNC milling machines, lathes, drilling machines or grinding machines, where they enable precise motion control and positioning of the tools. They help to increase manufacturing accuracy and are capable of transmitting high torques and speeds, which increases the efficiency and reliability of machining processes many times over.

Our design engineers can provide you with a broad technical spectrum for the realisation of such sophisticated concepts, which significantly improves the precision, performance and durability of a machine tool. Thanks to an application-specific design, we enable high load capacity, vibration-free operation and a long service life.

A hydraulic motor gearbox, for example, can be the ideal solution for such demanding applications. It has generously dimensioned bearings and has a lower slip oil quantity compared to hydraulic motor direct drives of the same series. The high level of efficiency is reflected in the outstanding torques with smoother running and the responsive drive due to the low inertia.

Cases of application

- phase shifter gearbox for the adjustment of grinding tools during honing

- low-backlash planetary speed-change gear for main drives of machine tools; hydraulically shiftable; PTO shafts according to the customer’s request

- phase shifter gearbox for the adjustment of edges during reaming with high-reduction planetary stage

- low-backlash sawing gears with adjustable circumferential backlash

Power transmission for every - really every - application.

What do our customers do with our gearboxes?

Spinning, compressing, pumping, labelling, sieving, stirring, sawing, welding, honing, drilling, navigating, screwing, printing, mangling, positioning, deep drawing, mowing, packing, cutting, reshaping, enveloping, fertilising, milling, flying, burning, washing, punching, compressing, braking, folding, kneading, weaving, winding, mixing, screwing, pressing, spraying, gluing, dosing, diagnosing, sealing, interlocking, pulling, perforating, testing, assembling, cutting, moving, transporting...

What purpose does your machine fulfil?